Heat Shield Cerfractory Chimney Relining Services

HeatShield® Restores Your Chimney

HeatShield® is a specially formulated “Cerfractory®” sealant material that restores the integrity of your chimney’s flue to vent hazardous flue gases from your home. It eliminates the dangers in your chimney caused by gaps, cracks, and spalling for years to come. By using either the Repair System or the CeCure® Sleeve Relining System (depending on the defects found) your chimney will be restored to its original peak level of safety and efficiency.

Chimney Repair Systems

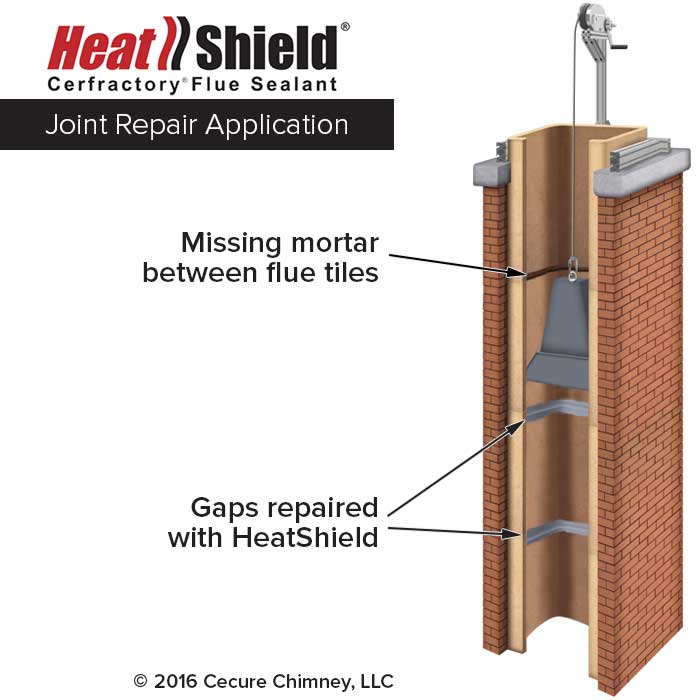

To repair chimney interiors, one of three methods are used. The Joint Repair System is used for chimneys that only require repair of defective mortar joints. The Resurfacing System is used to repair mortar joints and other minor defects in tile lined flues.

Joint Repair System

With our Joint Repair system, your chimney is fixed right, the first time.

First, a special foam applicator blade is custom made to fit your chimney. The applicator tool is then positioned below each gap or void.

The HeatShield® Cerfractory® Flue Sealant mixture is added. Each void in your flue is filled as the HeatShield® mixture is extruded into the void by the tool. Your repaired void is made smooth as the tool is pulled upward.

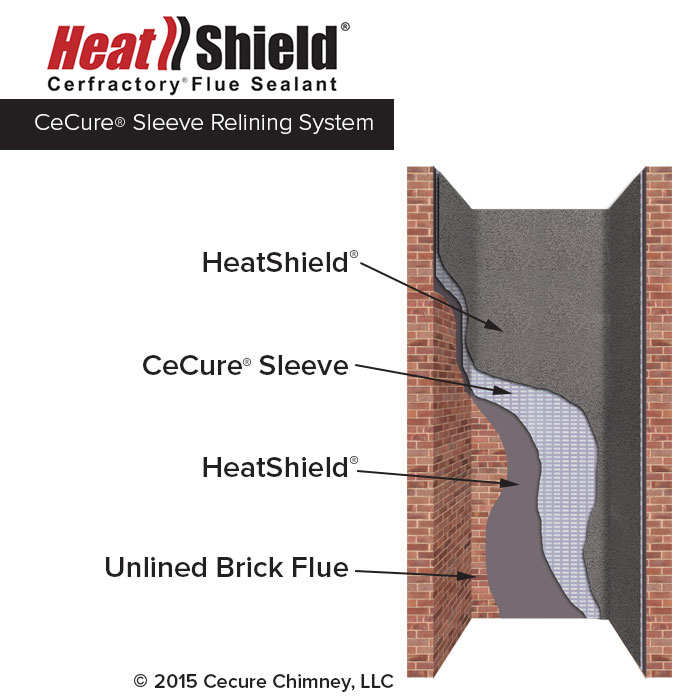

CeCure® Sleeve Relining System

In chimneys with more serious defects or unlined chimneys, HeatShield® can be used with the CeCure® Sleeve Relining System. The CeCure® Sleeve is a thin profile, ceramic insulation, reinforced with stainless steel fabric that is sandwiched between two coats of HeatShield® Cerfractory® Flue Sealant.

To reline your chimney with the HeatShield® CeCure® Sleeve Relining System (patent pending), an applicator plug is placed at the bottom of the flue and attached to a winch at the top of the chimney.

First, a coating of HeatShield® Cerfractory® Flue Sealant (with an added drying accelerator) is applied to the flue walls as the applicator plug is pulled upwards by the winch.

Second, a custom fitted, “CeCure® Sleeve” is lowered into the chimney and mechanically attached to the top of the chimney. The CeCure® Sleeve is a high density, low profile, ceramic insulation sleeve which has been reinforced with a special stainless steel fabric.

The applicator plug is then pulled downward through the CeCure® Sleeve to press it firmly into the first coating of HeatShield® Cerfractory® Flue Sealant with the added drying accelerator.

With the applicator plug at the bottom of the CeCure® Sleeve, the sleeve is temporarily clamped into place.

Lastly, another coating of HeatShield® Cerfractory® Flue Sealant is applied over the CeCure® Sleeve. Your HeatShield® Installer will then use a video camera to verify that the CeCure® Sleeve has been completely coated, ensuring the integrity of your newly relined chimney.

- Before HeatShield CeCure Sleeve

- After HeatShield CeCure Sleeve

HeatShield® Takes the "Heat" So You Don't Have To

Developed in Europe over 20 years ago, HeatShield’s® Cerfractory® technology is a hybrid (ceramic/refractory) coating and is proven effective both in use and by independent lab testing.

As a repair, it’s been proven to withstand moisture, corrosive flue gases, and temperatures in excess of 2900°F. It’s rated a “Super-Duty” refractory mortar per ASTM (American Society for Testing and Materials) C199. It surpasses both National Fire Prevention Association (NFPA) and International Residential Code (IRC) which require only a “Medium-Duty” refractory mortar for use in fireplaces and chimneys.

It is an approved “all fuel” chimney liner and listed to UL 1777 by Warnock Hersey with the addition of the CeCure® Sleeve.

Your Chimney Expertly Repaired

JC Heating is a certified HeatShield® Installer. HeatShield® Installers are carefully selected based on their industry certifications and experience. Armed with factory training and specially designed tools, JC Heating can expertly repair your fireplace chimney. Special video cameras are used to verify completed repairs.

Economical and Environmentally Friendly

HeatShield® is an “eco friendly” product made from recycled and naturally occurring materials. HeatShield® offers you and your chimney professional a less costly alternative to rebuilding your chimney or the destructive removal of flue tiles before the chimney can be relined.

20 Year Limited Warranty

Whether your chimney requires repair or relining, HeatShield® is covered by a 20-year manufactures material warranty.

How These Hidden Dangers Can Affect You

Fire & Health Risks

These defects, no matter how small, can begin a process that will further erode the chimney and can pose a threat to your family’s health. When heat, moisture and gases escape through gaps and cracks in your chimney, they can deteriorate your chimney from the inside out.

More importantly, the gaps and cracks can cause health risks, by allowing poisonous gases to escape into your home. Combustible creosote or soot can also escape through these openings and build up outside the flue liner. If the creosote catches fire in this area of your chimney, serious damage can occur, because the fire can no longer be contained within the flue.

Pieces of flue tile that flake off due to spalling can form dangerous blockages within your chimney.

Loss of Efficiency

Chimneys, to work correctly and efficiently, must be gas tight and free of gaps and cracks. Gases rising up through your chimney are similar to liquid being sipped through a straw. If the straw has a crack or hole in it the liquid will not flow effectively through it.

Gaps and cracks allow excess air into your chimney, slow the updraft and make it harder for smoke and gases to rise up and out. Hence, the fireplace, wood stove or furnace will perform poorly, resulting in the loss of heat efficiency.

Chimney Safety Institute of America (CSIA)

According to the CSIA (csia.org), problems such as gaps, cracks and spalling in your chimney's flue can present serious risks to your home and family, because your chimney can no longer perform its intended function - to safely contain and vent the products of combustion to the outside.

Building Codes

Building codes and fire standards require that chimneys are structurally sound, durable, smoke tight and capable of conveying flue gases to the outside completely and safely.

National Fire Protection Association (NFPA)

If the flue liner in a chimney has softened, cracked or otherwise deteriorated so that it no longer has the ability to contain the products of combustion (i.e., heat, moisture, creosote, and flue gases), it shall be removed and replaced, repaired or relined..." NFPA 211-Standard for Chimneys, Fireplaces, Vents and Solid Fuel-Burning Appliances (2006).

For over 48 years we're proud to provide chimney, heater and fireplace inspections & repairs to the following communities near me in Bucks County and Montgomery County , PA: - In My Area

Andalusia Pa, Bensalem Pa, Bristol Pa, Buckingham Pa, Churchville Pa, Cornwells Heights Pa, Croydon Pa, Doylestown Pa., Fairless Hills Pa, Feasterville Pa, Furlong Pa, Jamison Pa, Langhorne Pa, Levittown Pa, New Hope Pa, Newtown Pa, Newportville Pa, Near Me, Hatboro Pa, Hulmeville Pa, Horsham Pa, Richboro Pa, Trevose Pa, Tullytown Pa, Warminster Pa, Washington Crossing Pa, Wrightstown Pa, Wycombe Pa, Eddington Pa, Edgely Pa, Fallsington Pa, Feasterville Pa, Holland Pa, Hulmeville Pa, Ivyland Pa, Southampton Pa, Middletown Township Pa, Northampton Pa, Oakford Pa, Parkland Pa, Penndel Pa, Penns Park Pa, Wrightstown Pa, Morrisville Pa,and Yardley Pa. and surrounding area near me.